We will respond to your enquiry within 24 hours, quote your project within 2 working days A.S.A.P and update order schedule to you each week.

Our competitive price comes from most Chinese attractive advantages, such as lower labor cost, mass well educated employees, continuous improvement of equipment and technology. Our perfect production performance could be a great surprise to you.

We carry out project management method, and each project manager will be in charge of your project completely, from the quotation to the delivery of the completed mold or part.

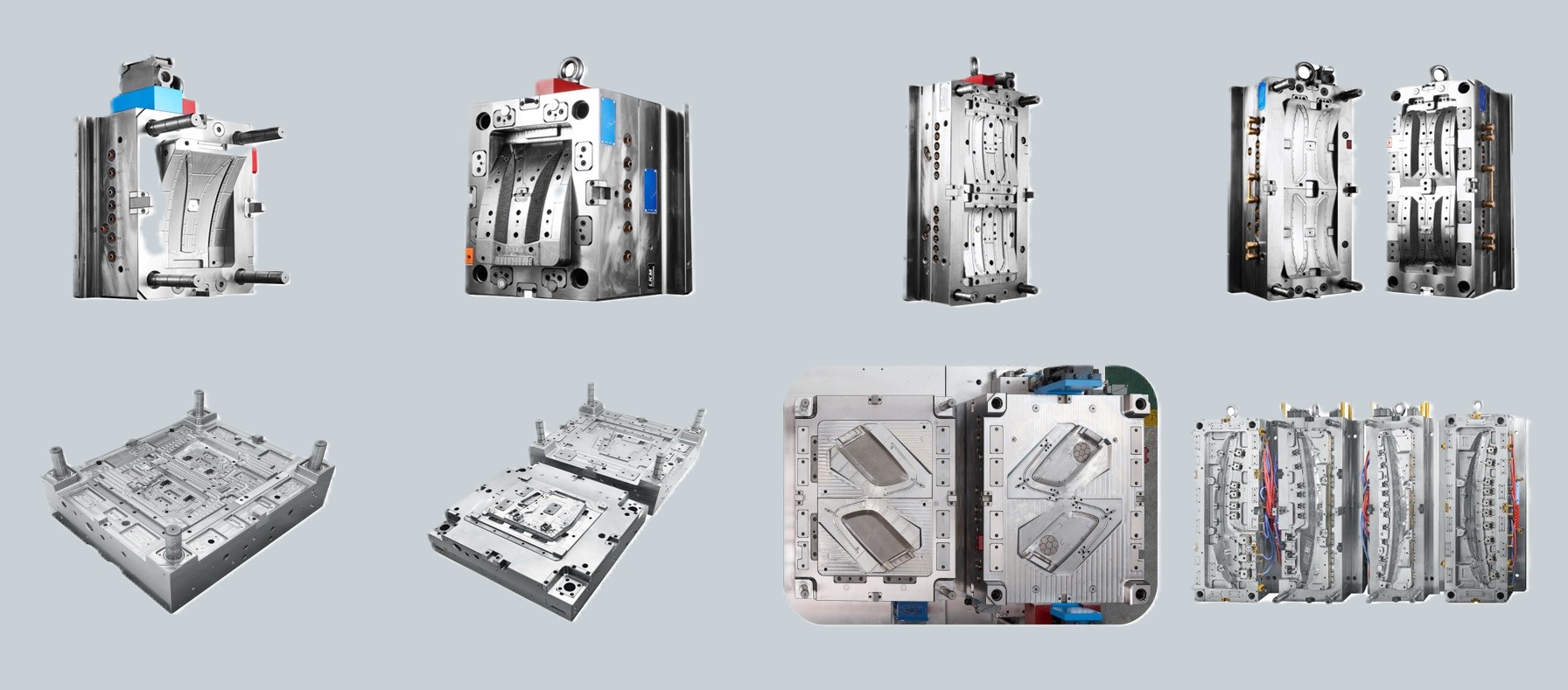

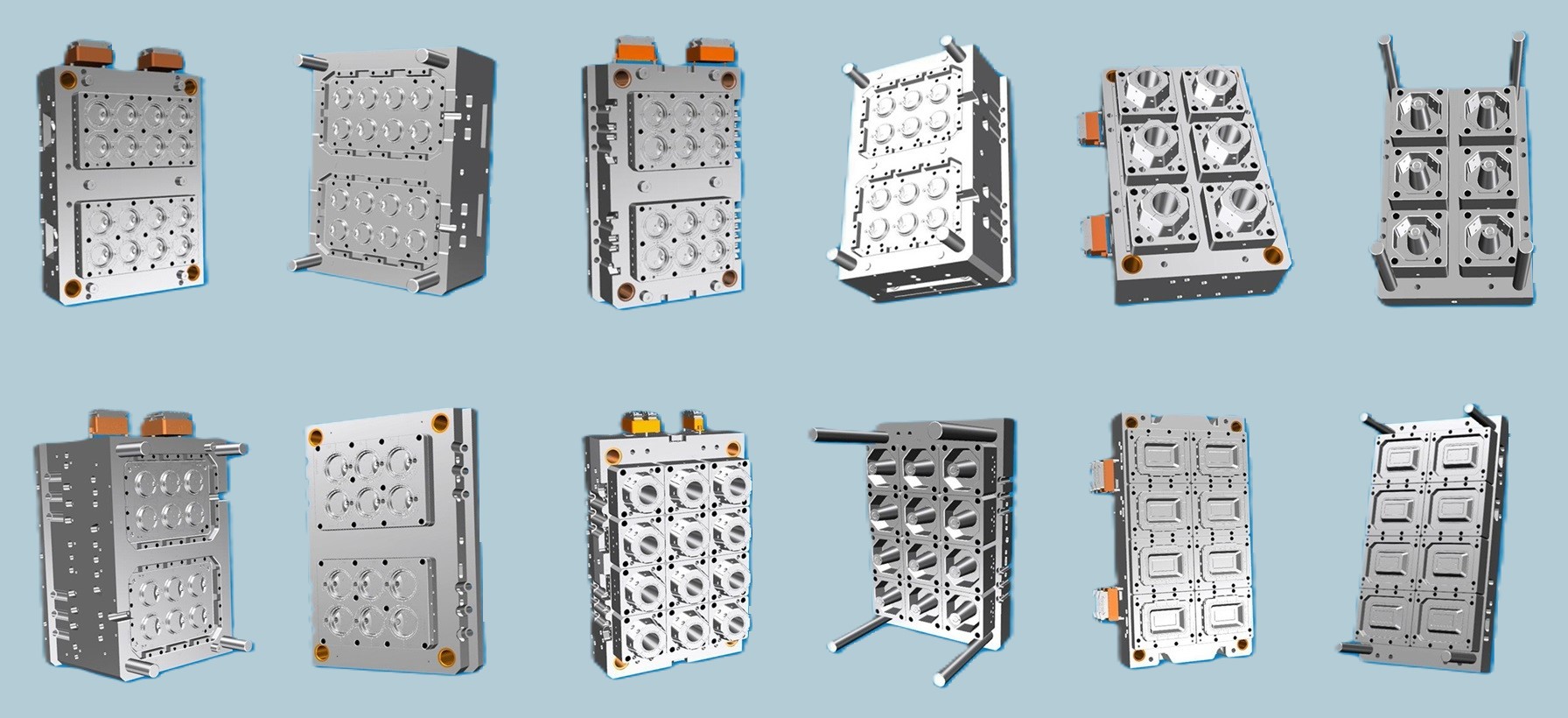

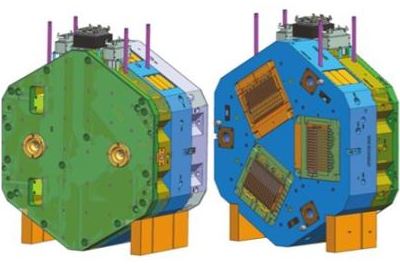

We are specialized in making plastic injection molds, die casting molds, molding parts, CNC machining parts, secondary operation and assembly service, most of the processes are done in-house, one stop service likes a package, enabling you to place one order for all your needs & save money - a family firm, well ensure your needs are met.

H T Mould (China) Limited was founded in 2001, specializing in manufacturing plastic molds and plastic injection molded parts. H T Mould was focus on overseas market. We have two factories one located in Shenzhen City and specialize in producing molds for a wide range of industries: automotive, home appliances, medical equipment, electronics, sporting goods, alloy toy vehicles and electronically controlled toys. Second Factory located in Dongguan City specialize in thin wall product mould making. As food package product have increased rapidly in the past decade. With continuous endeavor and innovation, we developed from a small company into a mold manufacturer of considerable size, running a manufacturing factory in mainland China with over 100 employees. We have successfully developed many projects, including all kinds of the plastic and metal components, such as auto parts, medical devices parts, telecommunication facility parts, office machine parts, consumptive electronics parts and home appliance parts etc. We working hard for the highest quality, best delivery, excellent service and competitive price, and have good reputation from our customers throughout the United States, Europe and Australia. Please don't hesitate to contact us for any assistance, we are looking forward to serve you at any time.

DOWNLOAD OUR PROFILEHere you can see some of our mould producing on the injection machine. And also you can see our plant overview. We have strong experience in thin-walled product mould making.

We provide a wide range of services to help clients with all of the front-end work that goes into a product before actual production begins. Some of those services include preliminary design, material selection, pricing, mold design, evaluation and procurement, CAD/CAM, surface modeling, and communication with the customer's engineering department. For each part we manufacture we will do the DFM study and mold flow analysis which will improve and support the mold structure design.

We use the design concept Molder-friendly which sets us apart from the competition. We bring you a combination of the best resources available; high technology equipment, quality workmanship, and program management and product development techniques that are flexible enough to meet the needs of your special requirements that can assist the molder or worker and save time and cost.

Our experience shows that the designer works within the context of an existing production system that can only be minimally modified. However in some cases, the production system will be designed or redesigned in conjunction with the design of the product.

Our expertise in CAE (computer aided engineering) in conjunction with the experience of hundreds of molded products provides a valuable link to reach the goal of producing quality products at the lowest cost and in the shortest time.

We provide a wide range of services to help clients with all of the front-end work that goes into a product before actual production begins.

We Believes good equipment can do the good job. So we always use the correct machine to do the correct job.

We focus on automotive, electronics, medical and industrial products field.